Advanced Plunger Hydraulic Cylinders: Engineered for Excellence

Discover the Precision and Durability of Our Plunger Hydraulic Cylinders, Tailored for High-Efficiency Operations Across Construction, Manufacturing, and Automotive Industries.

PLUNGER HYDRAULIC CYLINDERS

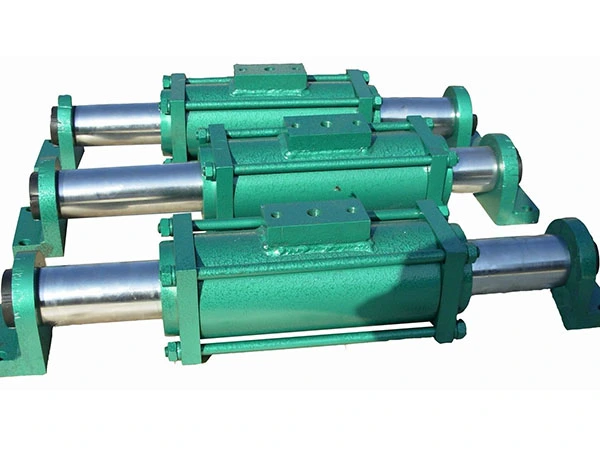

Compact Power

This small but mighty plunger hydraulic cylinder demonstrates how compact designs can deliver significant power, ideal for tight spaces in machinery.

Rugged Construction

Featuring a robust build, this plunger hydraulic cylinder is designed to withstand harsh environments, perfect for heavy-duty industrial applications.

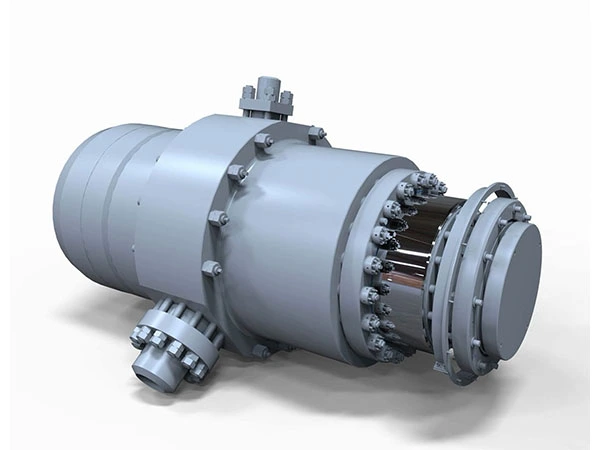

Precision Engineering

Showcasing precise engineering, this cylinder provides exceptional performance and accuracy for high-demand systems.

High-Capacity Lifting

Engineered for maximum lifting power, this plunger hydraulic cylinder is crucial for operations requiring high lift capacities, such as construction and mining equipment.

Sleek and Efficient

This cylinder combines sleek design with efficiency, making it a top choice for modern, energy-conscious industrial applications.

Customizable Solution

Custom-built to meet specific client requirements, this plunger hydraulic cylinder can be tailored in size, material, and pressure specifications.

Extended Reach

Ideal for applications requiring a long reach, this plunger hydraulic cylinder extends significantly, providing versatile functionality in hydraulic systems.

Heavy-Duty Performance

Built for the toughest tasks, this heavy-duty plunger hydraulic cylinder is perfect for applications that demand durability and power, such as in the mining and logging industries.

Plunger Hydraulic Cylinder Manufacturer

Introduction to Plunger Hydraulic Cylinders

Overview: Plunger hydraulic cylinders, also known as single-acting cylinders, utilize a plunger, which is a type of piston, to generate force. Unlike traditional cylinders, the plunger only moves in one direction and the force is generally exerted in a push action.

Functionality: The basic mechanism involves hydraulic fluid entering a sealed chamber, pushing against the plunger, which then extends out of the cylinder body. As hydraulic fluid is only on one side of the plunger, these cylinders are typically used where space and weight considerations are critical.

FEATURES & BENEFITS

High-pressure Operation

Designed to withstand and operate under extreme pressure conditions.

Robust Design

Features a simple yet powerful plunger mechanism made from high-grade materials.

Low Maintenance

Requires minimal upkeep due to fewer moving parts and high-quality construction.

Increased Productivity

Optimizes operational speeds and reduces downtime.

Cost Efficiency

Longer life span and reduced repair costs due to durable design.

Versatility

Ideal for both industrial applications and mobile equipment.

TECHNICAL SPECIFICATIONS

Our Plunger Hydraulic Cylinders are meticulously designed to suit a range of industrial demands with the following technical characteristics

Diameter Range

Available in sizes from 20 mm to 800 mm for the plunger diameter, allowing for a broad spectrum of force capacities.

Stroke Length

Offered in stroke lengths from 50 mm to 2000 mm, tailored for various application depths and operational needs.

Pressure Capacity

Capable of operating under pressures up to 400 bar, making them suitable for heavy-duty applications.

Operating Temp.

Designed to perform within a temperature range of -20°C to 100°C, ensuring reliability under various environmental conditions.

Construction Material

Built with high-strength steel, stainless steel, or aluminum options to match application-specific requirements regarding strength, corrosion resistance, and weight.

Seal Options

Equipped with polyurethane, PTFE, or NBR seals, selectable based on the operating environment to ensure optimal performance and durability.

Mounting Options

Available with diverse mounting styles such as flange, foot, clevis, or trunnion, facilitating various installation configurations.

Major Components of Plunger Hydraulic Cylinder

A Plunger Hydraulic Cylinder is comprised of several key components that contribute to its function and durability.

Each component is crafted with precision to ensure the entire assembly works flawlessly under demanding conditions. Understanding these specifics helps in selecting the right cylinder for your application and ensures that maintenance can be conducted effectively.

Cylinder Barrel

The main body of the cylinder which houses the plunger and the hydraulic fluid.

Cylinder Cap

Seals one end of the cylinder and is typically where the hydraulic inlet/outlet ports are located.

Gland

eals the other end of the cylinder from which the plunger protrudes. It often contains wiper seals to clean the plunger as it retracts into the cylinder.

Ports

Inlet and outlet ports for hydraulic fluid, strategically placed on the cylinder barrel or end caps to control the flow of hydraulic fluid into and out of the cylinder.

Plunger

A solid rod that moves in and out of the cylinder barrel. Unlike typical hydraulic cylinders, it does not have a piston attached to its end; the cross-sectional area of the plunger itself acts directly against the hydraulic fluid.

Seals

Various seals are used within the cylinder to prevent leaks and maintain pressure. These include static seals between the non-moving components and dynamic seals along the moving plunger.

Guide and Bearing

These components support the plunger as it moves, maintaining alignment and reducing lateral load-induced wear.

Installation Guide: Detailed Steps for Plunger Hydraulic Cylinders

Overview: Our plunger hydraulic cylinders are engineered for straightforward installation, accommodating various mounting styles to suit diverse machinery layouts. Follow these detailed steps to ensure optimal performance and longevity:

Preparation:

- Ensure all installation surfaces are clean and free from debris.

- Check the delivery package to ensure all necessary parts, such as bolts and washers, are included.

Choosing the Mounting Type:

- Flange Mounting: Ideal for fixed positioning, offering high strength. Align the flange holes with the mounting surface and use high-tensile bolts to secure.

- Foot Mounting: Provides a stable base for vertical or horizontal applications. Position the cylinder foot on a flat surface and secure using anchor bolts.

- Trunnion Mounting: Best for applications requiring the cylinder to pivot. Secure the trunnions in their brackets and check for free movement.

Alignment:

- Carefully align the cylinder along its operational axis to ensure it remains parallel to the path of the load. Misalignment can cause excessive wear and tear and operational inefficiency.

- Use a level and measure from multiple points to confirm alignment.

Securing the Cylinder:

- Tighten all connections to the manufacturer’s specified torque settings.

- Double-check all fittings to ensure they are secure and correctly positioned.

Final Inspection:

- Inspect the entire assembly for any loose components.

- Ensure hydraulic connections are tight and free from leaks.

Maintenance Tips: Ensuring Durability and Efficiency

Regular maintenance is crucial for the durability and efficient operation of hydraulic cylinders. Follow these detailed guidelines:

Hydraulic Fluid Maintenance:

- Check Fluid Levels: Regularly check the hydraulic fluid level and top up if necessary. Low fluid levels can lead to poor cylinder performance and increased wear.

- Replace Fluid: Change the hydraulic fluid according to the manufacturer’s guidelines or annually. Use the recommended fluid type to prevent damage and maintain system integrity.

Seal and Fitting Inspections:

- Inspect Seals: Check for signs of wear or damage in the seals. Replace any seals that show signs of deterioration to prevent leaks and maintain pressure integrity.

- Leak Checks: Regularly inspect the fittings and connections for leaks. Tighten or replace fittings as required to ensure a secure and leak-free system.

Plunger and Cylinder Care:

- Clean the Plunger: Regularly clean the plunger surface to remove dirt, debris, or corrosive materials that can cause wear.

- Check for Corrosion: Inspect the plunger and the inside of the cylinder for signs of corrosion. Apply protective coatings or lubricants as recommended to protect against corrosion.

Scheduled Inspections:

- Conduct detailed inspections of the hydraulic cylinder system every six months or according to the operational intensity.

- Document all maintenance activities and keep records to track the condition and servicing history of the cylinder.

By adhering to these detailed installation and maintenance guidelines, you can ensure that your plunger hydraulic cylinders operate efficiently and have an extended operational life, thereby reducing downtime and maintenance costs.

Start Today!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 8 hours.

- +86 755 3360 3110

- +86 159 8989 1944

- info@hydroforcecylinders.com