Reliable Power: Tie Rod Hydraulic Cylinders for Heavy-Duty Applications Description:

Our Tie Rod Hydraulic Cylinders are built to handle the toughest jobs with ease. Durable, reliable, and perfect for a range of heavy-duty applications. Whether you need standard or custom options, these cylinders deliver the power you need to keep things running smoothly.

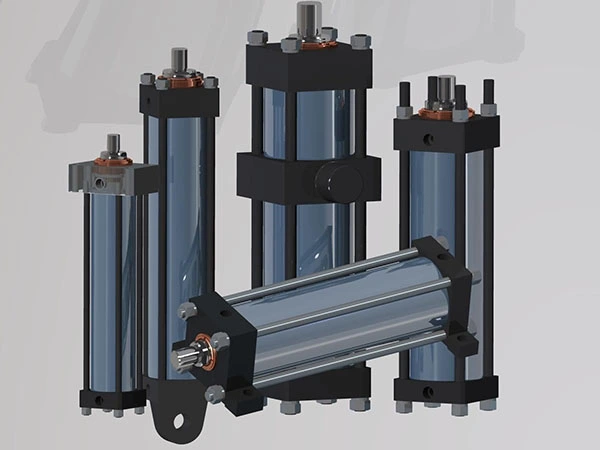

TIE ROD HYDRAULIC CYLINDERS

Tie Rod Hydraulic Cylinder Manufacturer

Introduction to Tie Rod Hydraulic Cylinders

Tie rod hydraulic cylinders are the go-to choice for heavy-duty applications, thanks to their sturdy build using tie rods to keep everything tight and right. These rods run through the cylinder’s end caps, clamping them to the barrel, which helps handle high pressures without a hitch. This setup not only boosts the cylinder’s strength and lifespan but also makes maintenance a breeze—just unscrew the rods, and you’re in. They’re perfect for jobs that need precise control and lots of power, like in construction or manufacturing machinery. Plus, you can tailor them to fit your needs, from size to strength, making them super versatile for any tough task.

FEATURES & BENEFITS

Adjustable Mounting Options

Versatile configurations for easy installation in any setup.

High-Strength Tie Rods

Designed for high pressure and load-bearing applications.

Custom Seal Packages

Tailored to operate efficiently under any environmental condition.

Operational Reliability

Performs under the toughest conditions without compromise.

Enhanced Longevity

Reduced wear and tear with our advanced sealing technology.

Ease of Maintenance

Designed for easy access and quick repair.

TECHNICAL SPECIFICATIONS

These specifications ensure that tie rod hydraulic cylinders can meet a broad range of industrial demands, offering robust performance, reliability, and adaptability for heavy-duty applications.

Operating Pressure

Typically designed to handle up to 3,000 psi, with models available that can withstand even higher pressures for more demanding applications.

Stroke Length

Stroke options range from a few inches up to several feet, ensuring suitability for various operational distances and tasks.

Bore Size

Available in a range from 1 inch to 24 inches, allowing for customization based on the force required for specific applications.

Rod Diameter

Proportionate to bore size for optimal performance, with larger diameters available for increased load-bearing capacity and stability.

Body Material

Constructed using high-strength steel or aluminum for lightweight options, providing durability and resistance to corrosion and wear.

Seals

Equipped with high-quality polyurethane or nitrile seals to prevent leaks and maintain pressure, with options for extreme temperature and chemical-resistant materials.

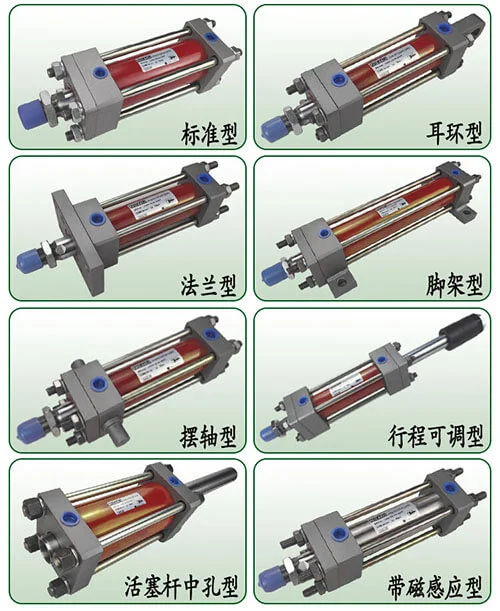

Mounting Options

Available with multiple mounting styles such as flange, clevis, foot, and trunnion mounts, allowing for flexible installation in various orientations and machinery setups.

Tie Rods

Made from hardened steel to ensure structural integrity and withstand the operational forces, the number and size of tie rods are adjusted according to cylinder size and pressure ratings.

Major Components of Tie Rod Hydraulic Cylinder

Tie rod hydraulic cylinders are composed of several key components, each crucial to their function and performance. Here are the main parts that make up these robust system.

All these parts team up to turn hydraulic power into mechanical action, making tie rod hydraulic cylinders perfect for handling lifting, pushing, and pulling jobs in rough industrial environments.

Cylinder Barrel

This is the cylinder's core, made from high-strength steel, often 45# steel, which is renowned for its durability and ability to withstand high pressures. It houses the piston and hydraulic fluid.

Piston

Nested inside the barrel, the piston moves back and forth, powered by the hydraulic fluid. It's crucial for transforming hydraulic power into mechanical force. It’s typically made from durable materials like stainless steel to resist wear and manage the stress of movement.

Piston Rod

Extending from the piston, this rod is usually crafted from hardened steel, like 1045 or 4140, known for its high strength and resistance to bending and wear. This rod connects the hydraulic force to the machinery or load.

Rod Seal

Essential for preventing hydraulic fluid leaks, the rod seal around the piston rod is usually made from polyurethane or nitrile rubber, materials chosen for their durability and effectiveness in maintaining seal integrity under varying pressures and temperatures.

End Caps

These secure the ends of the barrel and are typically made from the same high-strength steel as the barrel. They not only seal the cylinder but also provide mounting points that are integral to the cylinder’s installation and operation.

Wiper Seal

Positioned at the cylinder's opening where the rod exits, this seal cleans the rod to prevent contaminants from entering the cylinder. Materials like Teflon or polyurethane are used for their excellent debris-clearing abilities and durability.

Ports

These are the entry and exit points for hydraulic fluid, located strategically on the cylinder body or end caps. The ports are crucial for the controlled flow of hydraulic fluid in and out of the cylinder, facilitating the piston's movement.

Tie Rods

Stretching from one end cap to the other, tie rods are made from hardened steel, ensuring they hold the cylinder assembly securely under high operational pressures. They are critical for maintaining the structural integrity of the cylinder.

Installation Guide: Detailed Steps for Tie Rod Hydraulic Cylinders

Pre-Installation Preparation

- Inspect the Cylinder: Before installation, inspect the hydraulic cylinder for any signs of damage during shipping, such as dents or scratches on the rod and body.

- Verify Components: Ensure all necessary components, including mounting brackets, seals, and hardware, are present and correct for the specific model.

Choosing the Mounting Type

- Select the Appropriate Mount: Determine the most suitable mount for your application—flange, foot, clevis, or trunnion. This choice depends on the cylinder’s role and the machinery’s design.

- Prepare the Mounting Surface: Clean the mounting surfaces on both the machinery and the cylinder to remove any debris or corrosion. Ensure surfaces are flat and undamaged to provide a solid foundation for installation.

Aligning the Cylinder

- Position the Cylinder: Carefully place the cylinder in its designated location, aligning it with the machine’s operational axis.

- Check Alignment: Use a level and measuring tools to ensure the cylinder is perfectly aligned in all axes. Misalignment can cause excessive wear and premature failure.

Securing the Cylinder

- Attach Hardware: Secure the cylinder to the machine using the bolts, nuts, and washers provided. If your cylinder uses tie rods, ensure they are evenly tightened across all ends to maintain equal pressure.

- Torque Specifications: Refer to the manufacturer’s specifications for the correct torque settings. Use a torque wrench to tighten all fasteners to these specified torques to avoid over-tightening, which can warp or crack mounts.

Hydraulic Connections

- Connect Hydraulic Lines: Attach the hydraulic hoses or pipes to the cylinder’s ports. Ensure that all fittings are clean and correctly aligned before tightening to prevent cross-threading and leaks.

- Secure Fittings: Use wrenches to tighten the hydraulic fittings to the manufacturer’s recommended torque. Avoid over-tightening to prevent damaging the threads.

System Check

- Leak Test: Once the hydraulic connections are secure, slowly pressurize the system and check for leaks around all fittings and seals.

- Operational Test: Activate the cylinder several times to ensure it moves smoothly without binding or hesitation. Listen for any unusual noises that might indicate issues with alignment or hydraulic flow.

Final Inspection

- Inspect for Movement: Ensure there is no unnecessary movement in the mounting points when the cylinder is in operation.

- Re-check Alignment: After the initial operation, re-check the alignment and make adjustments if necessary.

Maintenance Tips: Ensuring Durability and Efficiency

Taking good care of your tie rod hydraulic cylinder is key to keeping it in top shape and avoiding costly downtime. Here’s a simple, but detailed guide to help you stay on top of maintenance:

1. Keep it Clean

- Wipe it Down: Regularly clean the cylinder, especially the piston rod, to get rid of dirt, grime, or any debris. Dirt can cause scratches on the rod, leading to seal damage and leaks. Use a soft cloth and avoid harsh chemicals.

- Check for Rust: If you notice any rust forming, clean it off immediately and apply a light coat of protective oil to the rod to keep it smooth and rust-free.

2. Inspect Seals and Fittings

- Look for Leaks: Regularly check around the seals and fittings for any signs of oil leaks. If you spot a leak, it’s time to replace the seals or tighten the fittings.

- Check the Seals: Pay attention to the condition of the seals. If they look worn, cracked, or damaged, replace them before they cause bigger issues.

3. Monitor Hydraulic Fluid

- Check Fluid Levels: Always ensure that the hydraulic fluid levels are within the recommended range. Low fluid can cause the cylinder to work harder, leading to wear and tear.

- Fluid Condition: Keep an eye on the condition of the hydraulic fluid. If it looks dirty, milky, or has particles in it, it’s time for a change. Clean fluid helps the cylinder run smoothly and reduces wear.

4. Lubricate Moving Parts

- Grease the Bearings: Regularly lubricate the cylinder’s bearings and moving parts with the recommended grease. Proper lubrication reduces friction and prevents parts from wearing out too quickly.

- Avoid Over-Greasing: Don’t overdo it with the grease. Too much can attract dirt, which can then work its way into the cylinder and cause damage.

5. Check Alignment

- Stay Aligned: Make sure the cylinder stays aligned with its load. Misalignment can cause uneven wear on the seals and rod, leading to leaks or even rod bending.

- Adjust as Needed: If you notice any signs of misalignment, such as uneven wear or unusual noises during operation, adjust the mounting or align the cylinder immediately.

6. Regular Inspection

- Scheduled Checks: Set up a regular inspection schedule. Give the cylinder a thorough once-over every few months, checking for any signs of wear, damage, or leaks.

- Document Everything: Keep a maintenance log. Record all inspections, repairs, and fluid changes. This helps you keep track of the cylinder’s condition and anticipate when maintenance will be needed.

7. Protect from Overloading

- Know the Limits: Always operate the cylinder within its specified load and pressure limits. Overloading can cause serious damage and shorten the cylinder’s lifespan.

- Use Safety Valves: Install pressure relief valves to protect the cylinder from unexpected pressure spikes that could cause damage.

By following these maintenance tips, you’ll keep your tie rod hydraulic cylinder running smoothly and avoid unexpected breakdowns.

Start Today!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 8 hours.

- +86 755 3360 3110

- +86 159 8989 1944

- info@hydroforcecylinders.com